Cracking

Main source of pavement failure

Causes and consequences

The most common causes are heat shrinkage and fatigue due to traffic loads. There are also many other reasons that can play a decisive role in cracking a pavement, such as the effects of freeze/thawing, the effect of road geometry and constructive procedures.

This results in premature wear and tear, ultimately leading to failure of the structure as a result of an accelerated degradation cycle.

Short- and medium-term consequences

Not to mention the noise and sensory nuisance of a wheel in contact with a crack, there are notable consequences resulting from the presence of cracking on pavements:

- Decrease in pavement service life

Premature wear and tear, structural failures - Awareness of climate phenomena

Freeze/thaw, precipitation... - Increased danger to motorists

Variable adhesion - Traffic disruption

Areas of cracking and deterioration that can cause users to brake due to a lack of comfort or perceived safety.

In this context, Texum has developed innovative solutions, specific to each type of road structure, aimed at eliminating cracking phenomena while reinforcing the pavement structure.

Reflection cracking

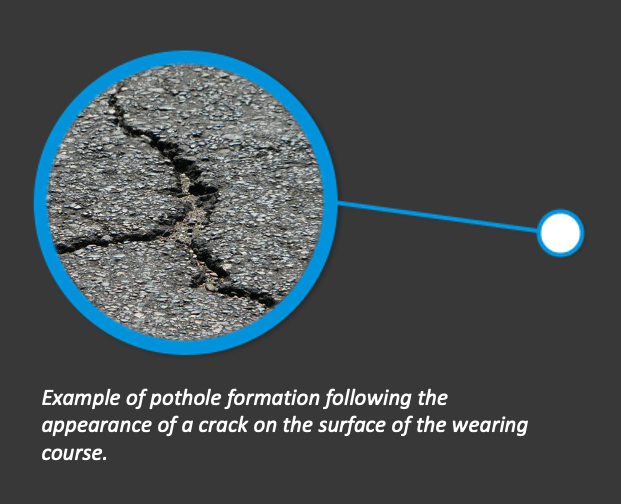

More commonly known as crack uplifting, this degradation occurs prematurely when new layers are applied to old, already cracked layers. They can also form in layers applied to a stabilized foundation that is subject to shrinkage.

This reflection cracking, more commonly referred to as cracks, is caused by the propagation of an existing crack in a structural layer below the wearing course (base and/or binder course). Without careful consideration of this parameter, the new tread will deteriorate as soon as possible.

Fatigue cracking

Fatigue cracking is a consequence of repeated cyclical applications and will occur when the pavement is going to experience cumulative traffic in excess of a permissible limit value.The ageing of asphalt mixes, which is synonymous with rigidification of the latter, is an aggravating factor in this cracking process.

When dimensioning a pavement, a traffic load is defined (associated with other parameters) in order to establish the road structure according to current standards.

During the pavement life cycle, vehicle density may increase. In the event that this event occurs, the structure absorbs more load cycles than initially expected, and is therefore the result of a phenomenon known as fatigue, prematurely.

To this is added the phenomenon of ageing of the asphalt mix forming the wearing course. The oxidation of the binder reduces the cohesion of the material, making it more rigid and especially more fragile: the pavement is then very sensitive to cracking.

Fatigue cracks have an evolutionary process similar to shrinkage cracks, but they differ in that they generally occur in the longitudinal direction. These cracks can affect all layers of the structure or be confined to the wearing course.

Thermal cracking

Thermal cracking results from temperature variations.

The properties of asphalt mixes vary according to the operating temperature and can therefore be modified depending on the weather conditions.

We may also note that the stiffening of asphalt mixes is an aggravating factor in this cracking process.

Consequently, when subjected to mechanical stress at too high a temperature, an asphalt mix - known as soft asphalt - may deform irreversibly under load.

As a result of these deformations, cracking problems can occur because the asphalt thickness is locally modified.

Conversely, the bituminous asphalt mix is stiffened, directly linked to the drop in temperature. When subjected to mechanical stress at too low a temperature, asphalt mixes tend to work under stiff conditions. This more rigid mix will accentuate the phenomenon of thermal cracking by its increased fragility.

Concrete, on the other hand, remains sensitive to temperature variations. Under the action of the cold, these materials contract, resulting directly in the initiation of thermal shrinkage micro cracks. Even if the type of concrete used and the thickness of the layer considered directly influences the shrinkage rate, any layer (of road structure) composed of concrete is subject to thermal cracking

TEXUM expertise

Cracking is a common phenomenon in road infrastructure.

Extensive studies have led us to develop solutions adapted to this problem in order to control it in a simple and economical way.

Depending on the situation considered, as well as the condition of the pavement, specific solutions are available to best meet your needs.

Solution TEXGRID® CV 150 COVERSolution TEXGRID® GV 120

Solution TEXGRID® CV 200

Swiss reinforcement company

Swiss reinforcement company