Rutting

Structural failure and security issues

Rutting, causes and consequences

Following repeated heavy vehicle traffic, a plastic and permanent deformation of the pavement can be observed.

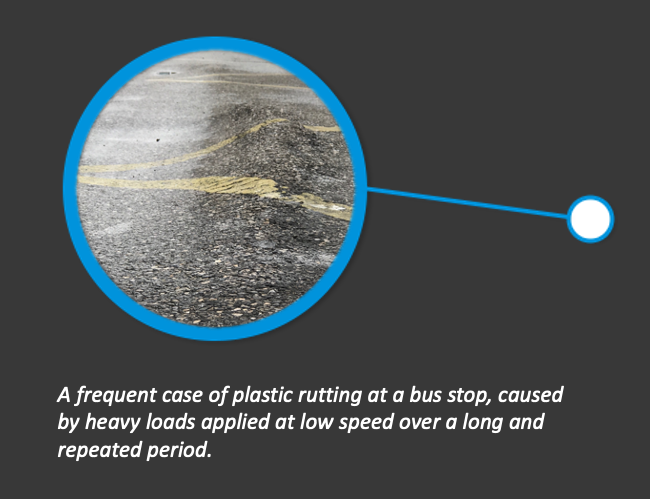

Longitudinally shaped, these deformations are present on localized portions of particularly stressed road sections, such as bus stops or intersections (standard or roundabouts).

The creation of ruts is often due to a lack of absorption of forces by the pavement, which is repeatedly subjected to high mechanical stresses.

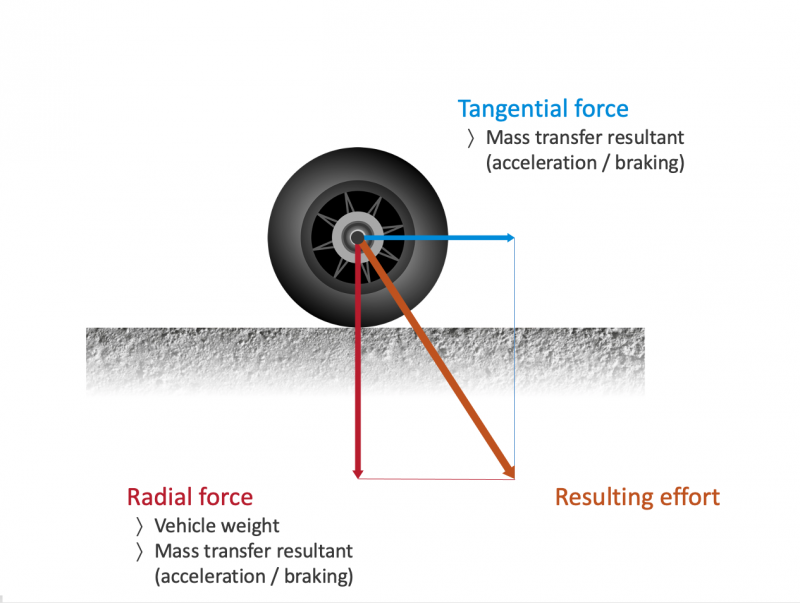

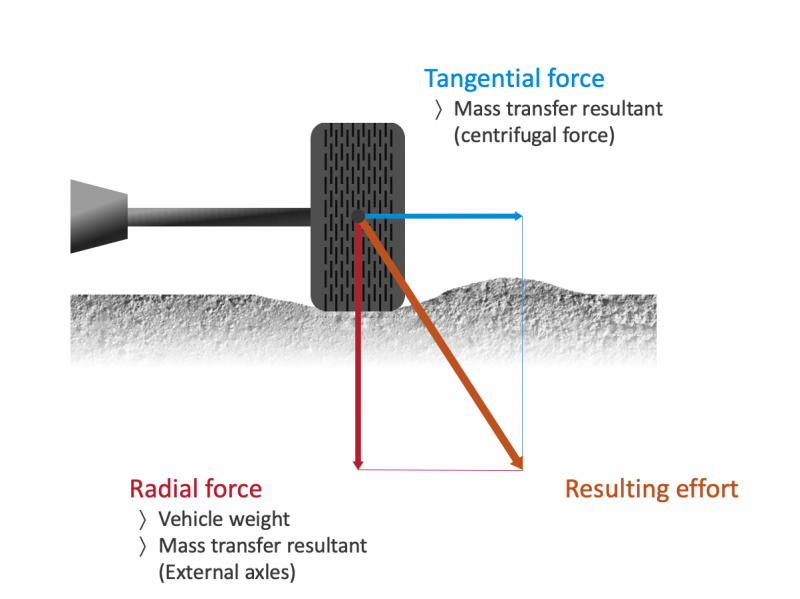

These applied mechanical forces are the result of the combination of two associated mechanical components:

- Radial force: association of weight and vertical acceleration of the vehicle under consideration

- Tangential force: resulting from weight by acceleration and mass transfer on axles

This degradation may be due to structural undersizing, or fatigue altering the initial mechanical properties of the pavement.

Creation of rutting: mode 1

The wheel of a vehicle exerts in this mode a radial (vertical) force composed of the weight of the vehicle (static component), combined with a mass transfer from the acceleration/braking phenomenon (dynamic component).

The tangential (horizontal) force is represented only by the horizontal component of mass transfer.

The resulting force is therefore not, in this case of application, perpendicular to the pavement surface.

Creation of rutting: mode 2

The constraints of this mode of creation are similar to mode 1, except that the dynamic (horizontal and vertical) results are now created by mass transfer due to centrifugal force.

It should be noted that modes 1 and 2 are often combined in acceleration/braking zones during cornering (e. g. roundabouts, remote bus stops), making the reinforcement approach more complex, requiring specific solutions.

Security and structural risks

For these two modes of rutting creation, similar consequences are identified.

The rutting of bituminous layers is one of the main modes of potential degradation of pavements. This phenomenon cannot be tolerated at excessively high intensities for several reasons, putting into question the discomfort of users and their safety (even more important factors at high speed).This deformation poses many problems for road users. Water pockets are created in the event of moderate rainfall, favouring aqua-planning effects. Depending on the depth of the rut, this degradation can also easily endanger users travelling on two-wheelers (risk of falls), as this type of vehicle is sensitive to local variations in road surface level.

Numerous studies and research have been carried out on the use of black materials to limit this phenomenon, in particular by making these materials more rigid and therefore resistant to permanent deformation. However, these formulations are much more sensitive to fatigue cracking.

The formulation of a material that meets the mechanical requirements of rutting and fatigue cracking resistance is therefore a complex task, given the contradictory requirements of combating these two degradation modes, in terms of bitumen hardness or other binder content.

Whether this phenomenon is caused by undersizing or structural fatigue, each heavy vehicle passage will have an impact on the size of the rut in question: these damages must be treated quickly, before the only acceptable solution is the complete replacement of the structure.

Plastic rutting (small radius)

Plastic rutting - also known as "small radius rutting" - results from plastic deformation of the top layer (s) of bituminous mixes.

Simple corrective actions can be taken to remedy this phenomenon, which can cause considerable discomfort.

- High temperatures (or exposure temperature higher than that recommended for the asphalt mix)

- Repeated action of important constraints in specific areas (bus stops, roundabouts)

- High tangential forces (loaded)

- Loss of structural inertia due to detachment of asphalt layers

- Under sizing of bituminous layers

- Use of overly ductile mixes

The observed plastic deformation is in the form of creep. The depth of the rut will therefore be twice as deep as that represented by the material having flowed.

As a result, the creation of ruts is all the more rapid, while being associated with a self-generating character: the deeper they are, the faster the future degradation will occur.

Faced with this problem, road network managers often resort to surface operations, aiming at frequent replacement (all or part of) the wearing course, or at locally milling surplus material on the surface (burrs). However, this operation does not deal with the problem at its source, and therefore requires frequent interventions until the road structure is altered by this initially localized failure.

It can therefore be adapted to reinforce the surface subjected to these forces in a preventive way thanks to adapted solutions, as soon as ruts appear, so as not to let them degrade a healthy pavement.

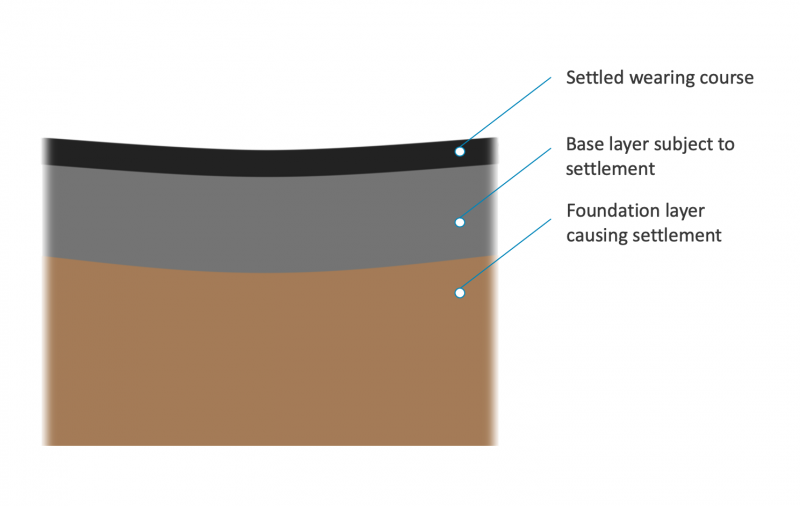

Structural rutting (large radius)

Structural rutting - known as "large radius rutting" - results from a significant settling of the non-bituminous pavement structure.

This compaction resulting from poor bearing capacity causes the pavement to collapse due to repeated poor absorption of surface loads..

The conditions of application, the nature of the base layer and the type of subfloor are factors that can lead to this phenomenon.

One of the existing solutions can be the total replacement of the existing structure, to ensure a complete takeover of the work. This long and very expensive procedure is generally only applicable in extreme cases, for which the use of the road in question can no longer be considered.

Alternative solutions, sometimes possible, offer less expensive services by reinforcing the existing bituminous structure in order to optimize the load distribution on the existing base layer.

TEXUM expertise

Our product range is built around solutions developed for specific applications and constraints.

Rutting remains a topical issue depending on many factors. Our engineers and technicians are at your disposal to accompany you in your analysis of the existing situation, in order to propose you the solution in adequacy with your problem.

Swiss reinforcement company

Swiss reinforcement company